Designing healthier housing is among the most challenging and critically important work that architects do. There is a growing need to mitigate pathogens. With increasingly alarming data on the detrimental effects of many chemicals found in nearly everything we use, the emerging fi eld of green chemistry and new building technologies off er opportunities to better address how the home environment impacts the health of occupants.

Like many firms, Magnusson Architecture and Planning (MAP) is considering all of this alongside other design approaches to health, such as biophilic, active, and trauma-informed design. We also view design in the larger context of resiliency and sustainability, including both reductions in operational and embodied carbon. While many of the strategies overlap, a closer look at materials and building systems can sometimes reveal competing objectives. At MAP, we’ve developed a six-point framework for balancing priorities to eliminate exposure to toxicants where possible and to manage exposure where necessary. Every building is different, but this resident-centered approach bolsters the common purpose of our clients and their communities, improves buy-in on design decisions, and builds the case for broader project support.

1. PROVIDE ACTUAL FRESH AIR

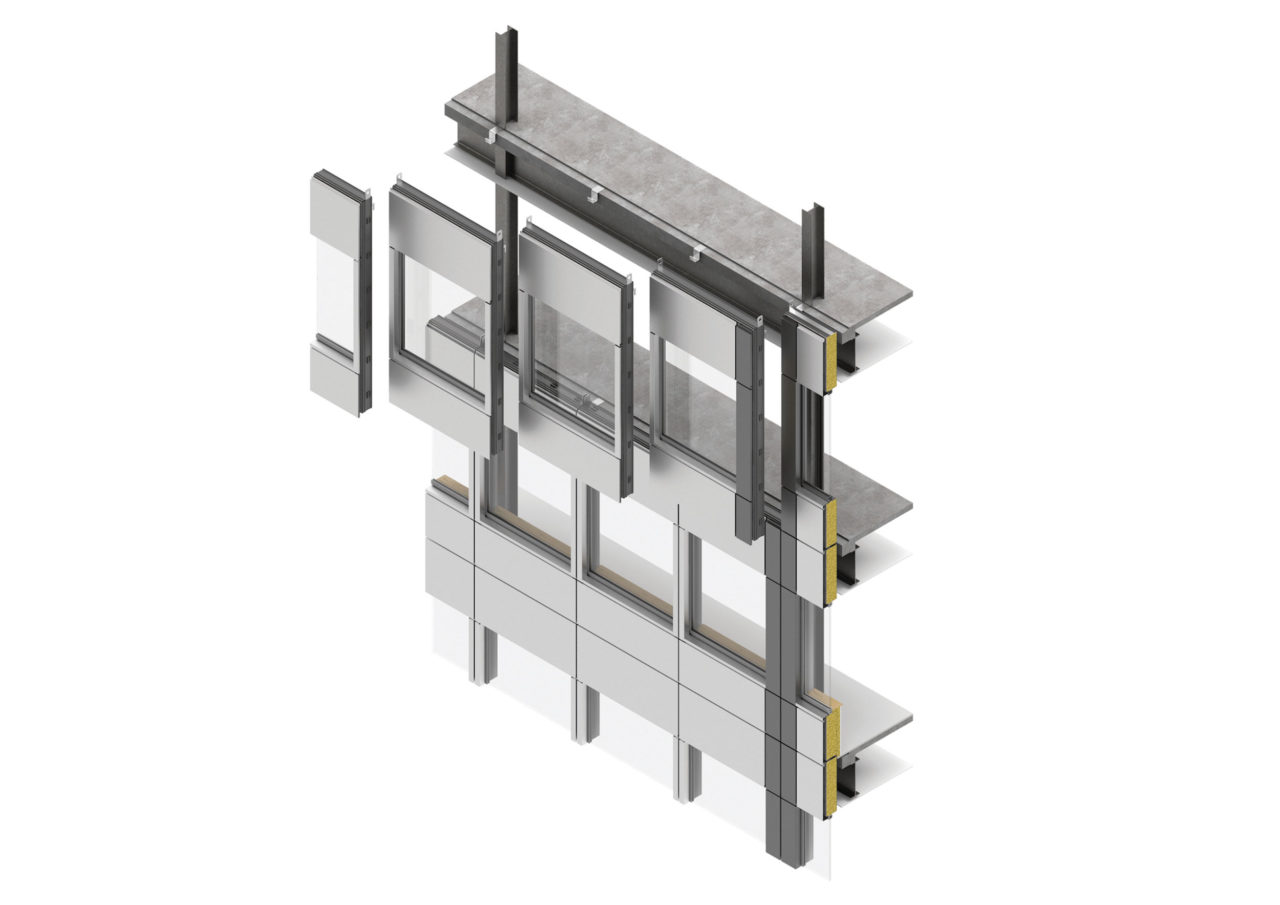

Current code anticipates that apartments will acquire some of their fresh-air allowance from leaky envelope construction. In a multifamily building with typical “exhaust-only” ventilation, negative pressure is created inside units, and about a third of the makeup air is sucked in through walls and under doors. In other words, fresh air comes through exterior walls and from shared spaces with neighbors, such as the corridor. Most measured as-built conditions of an exhaust-only building do not even result in the desired air changes. Not only is this an unsanitary way to replenish oxygen and remove particulates, germs, and toxicants from off-gassing materials or excess moisture, but a leaky building is also bad for asset durability and, of course, energy savings. Through RetrofitNY, NYSERDA is encouraging our industry to retrofit existing buildings to create healthier and efficient levels of airtightness. For example, Dextall (shown below) is an approved component manufacturer by NYSERDA for exterior cladding and is involved in the NYC Housing Authority’s deep energy retrofit.

An airtight structure is essential for energy efficiency, but once the building is airtight, ideally tested, and built to a Passive House standard, we need to ventilate deliberately with dedicated return and supply to ensure air changes. The best way to do this is with an energy recovery ventilator (ERV) unit, so we can capture the energy spent on space conditioning. This also allows us to filter the incoming fresh air, with a recommended minimum level of MERV 13 filter to further reducing toxin load. A “core” or plate heat exchanger-type ERV is a good option, as these have minimal risks for air transfer between streams inside the machine.

2. REDUCE “SHARED AIR”

Unit compartmentalization provides numerous benefits for healthy interiors, energy efficiency, and resident well-being, including improvements in odor, noise, and pest control and, critically, air quality. Apartment compartmentalization supports the true functionality of an ERV ventilation system and dramatically reduces pressures on the building through stack effect, which minimizes the transfer of air between apartments. This, in turn, can limit the transfer of pathogens.

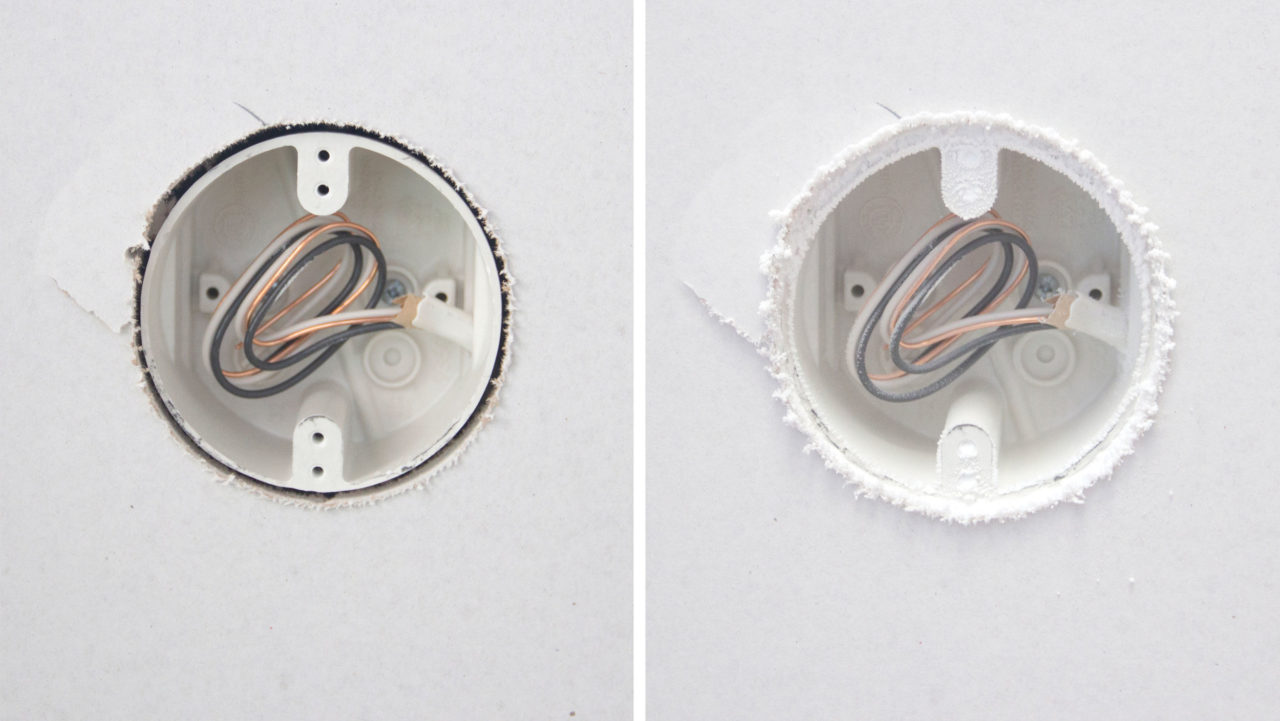

Apartment compartmentalization is required in affordable housing by certification with Enterprise Green Communities (EGC). Blower door tests of individual apartments are conducted to ensure they are airtight, meeting a maximum of 0.30 CFM50 per square foot apartment enclosure area. Building code requirements for Sound Transmission Class (STC) and fire ratings of tenant partitions, to seal walls and penetrations, result in nearly this level of airtightness already, as long as details to achieve these are diligently and fully implemented in the field. Therefore, those projects not required to participate in EGC can achieve this compartmentalization without adding scope—only an enhanced level of quality control is required. Blower door testing of a sample selection of units is a good idea, however, if you are working with an unfamiliar general contractor. For retrofit projects, this kind of air sealing at tenant partitions may be more difficult. One product solution here is AeroBarrier (shown above), which can be applied in a new construction or retrofit, after the unit has been pressurized. The product seeks and seals gaps as large as half an inch and as fine as a human hair.

3. GO ALL-ELECTRIC

While the push for all-electric buildings is often understood as a carbon reduction strategy, it also has significant implications for health. The burning of fossil fuels releases high quantities of particulate matter and other toxicants. Eliminating on-site combustion includes doing away with gas stoves, which emit nitrogen dioxide, carbon monoxide, and formaldehyde, each of which can exacerbate respiratory and cardiovascular ailments.

Electric resistance stoves are a common substitution, but induction stoves that require ferrous or magnetic cookware (most cookware is induction-ready) are an exciting alternative. They are more efficient, and most culinary artists agree they are great to cook with. Not only do electric and induction stoves release significantly less waste heat, keeping kitchens cooler, but induction stoves also work more efficiently, boiling 1.5 gallons of water in two instead of eight minutes for a gas stove.

Renowned chef and electric kitchens expert Chris Galarza not only advocates for induction cooking technology, but actually operated an all-electric kitchen for nearly six years before opening his own culinary consulting company, Forward Dining Solutions LLC. “Induction cooking technology is the future of cooking,” says Galarza. “It’s something that gave my team and me the edge to get more food out in less time. It allowed us to work faster to satisfy the needs of our guests, while staying cool and comfortable doing it. In our line of business, speed is king, and on a gas range we can cook nearly 39 pounds of food per hour. On induction, we can cook 70-plus pounds per hour.”

Moving away from fossil fuel-based systems also means specifying heat pump electric space conditioning systems. Heat pumps are always more efficient than combustion equipment because they do not generate heat—they move it around. Using these systems also provides an enormous resiliency benefit due to their ability to provide cooling as well as heating. This will be critical in NYC, as our climate and envelope energy-efficiency strategies are moving us to cooling-dominated interiors. That said, manufacturers have also solved cold-climate concerns, and they can now operate at much lower temperatures.

4. REMOVE FOSSIL FUEL-DERIVED MATERIALS

Avoiding fossil fuels is not just about on-site emissions: the concern extends to material composition. Therefore it’s important to eschew fossil fuel-based plastic insulation products, such as rigid foam boards and spray foam, as these are almost always required to contain chemicals such as flame retardants, which are bio-accumulative (meaning they don’t decompose, but rather build up in the food chain). These products may pass an NFPA 285 test, but they do so with these chemicals, and can still burn. Since plastic foam insulation is usually higher in global warming potential and perpetuates the use of fossil fuel-based products, phasing it out would contribute to overall planet health. We are still on the lookout for a 100% recycled content—zero chemical plastic insulation product that is straightforward to recycle at the end of its use.

The goal to avoid foam insulation should be set early in the process, as healthier options often require slightly different enclosure configurations. While it can be hard to avoid extruded polystyrene below grade, for example, an effective alternative is expanded glass gravel, also called “foam glass.” This is not the board insulation foam glass, and the “foam” here is not the same as the foam in spray foam, etc.; rather, it is a gravel product that has insulative value. This is especially useful in projects with lower water tables, where we can replace both rigid boards and the gravel layer below slabs. It can even be used where a Sub Slab Depressurization System (SSDS) is required. Two manufacturers/products in our area are Aero Aggregates (shown above) and Glavel. Large quantities of insulation are required to meet our near Net Zero operational goals, so careful review of insulation choice is a high-impact item.

5. ALIGN HAZARD WITH RISK WHEN SPECIFYING MATERIALS

When collaborating with clients and residents on interior material design, it is important to focus on high-touch, high-exposure locations. Often there are no perfect material choices, and therefore we lead with known health hazards, prioritize by identifying the health risks, and eliminate the chemicals that exacerbate these concerns.

It is not only important to specify materials that do not contain toxic chemicals, but to think about how they are installed, and whether coatings are necessary. For example, natural wood may require a toxic resinous coating, and countertops may require per-fluorinated chemical sealants. Instead, products that often meet more stringent health criteria are Plyboo bamboo flooring and Caesarstone Quartz Classic Collection (shown above) countertops.

If a product suits a project’s needs but contains a harmful chemical, talk with manufacturers to improve it. Sometimes, though, a material substitution is still required. For example, linoleum is a healthier material than luxury vinyl tile (LVT) and might be preferable, however, it does not always meet the durability or cleanability standards required for certain projects. Two products new to the market that are Red-List Free and meet our cleanability and durability requirements are Pivot Point by Mohawk Group (shown above) and Interface’s (shown above) carbon-neutral, Green Star-compliant LVT.

Another key strategy for removing toxicants is to simplify the material palette. This helps to focus research efforts on selections that will be most impactful to the project. We need to consider not only the people who occupy the new spaces, but those in fence-line communities where our building materials come from. Often, our efforts to limit exposure to toxic chemicals when a building is in use can likewise limit exposure for those who live in the places where materials are extracted and products are manufactured. This is not always the case, however, so every decision needs to consider the full life cycle of a product, including its production, durability, cleanability, recyclability, and more. The amount of investigation necessary can be extensive, but many resources and organizations are available to assist designers in making better choices. Maintaining an office library with healthy products prioritized is also extremely valuable.

6. CONSIDER GREEN CHEMISTRY AND ENLIST EXPERT HELP

With better data from the last few decades concerning the longterm health effects of the chemicals we use in modern society, the relatively young field of green chemistry aims to “maximize efficiency and minimize hazardous effects on human health and the environment.” This work is essential because our regulatory infrastructure and approach to product development are not set up to protect us yet. Rather, our system facilitates the use of products that do not contain a handful of chemicals known to be toxic, and allows new chemicals to be utilized with limited testing requirements. In other words, the products are innocent until proven guilty, instead of tested until known to be safe. Of the more than 85,000 chemicals currently in use, the Environmental Protection Agency has regulated only eight.

Only more recently has the makeup of products and their potentially hazardous ingredients even been disclosed. The move for transparency is gaining urgency in our industry as we become more aware of what we are dealing with. While web sites and studies can help identify hazards, it is up to designers and their consultants to weigh exposure risks and compare products. Key to this process is using Health Product Declarations (HPDs) and Environmental Product Declarations (EPDs). Managed by the non-profit HPD Collaborative, the HPD standard reports product ingredients (down to 100 ppm or 1000 ppm) along with their known hazards. These are different from MSDS/SDS sheets because they report (almost) all ingredients, even if they are not deemed hazardous by the manufacturer. Also, SDS sheets focus on the impacts to installers only.

EPDs are a summary of a product’s life-cycle assessment (LCA), focusing on key environmental degradation effects called “impact categories.” The number of these categories and the rules for perform-ing the LCA is defined by product category rules, which are developed and agreed upon by the collective manufacturing industry of that product. An EPD may address only the manufacturing process (“cradle to gate”) or can attempt to span the entire life cycle (“cradle to cradle/grave”). EPDs are currently being most widely used to assess products’ global warming potential (GWP) in kgC02 or “embodied carbon.” EPDs represent a well-established methodology and can be used for comparison, but were originally intended for manufacturers to track internal progress and are only now being adapted for a broader use. Thus, great care is needed to take into account several nuances before truly making a com-parison. The rules for HPDs and EPDs are also in a current state of flux, so it is important to check in with those who can provide expert guidance, be they architects, engineers, sustainability consultants, etc.

A PLEDGE FOR THE FUTURE

While the complexity of this work can seem daunting, it is also empowering to understand the immense and critical role that architects can play in improving and maintaining the health of those who use their buildings. As we make choices about building systems or materials, or advocate with clients, government regulators, manufacturers, and so many others in the industry, we can be the linchpin in this critical endeavor. And, although this is not a comprehensive list of all the health interventions an architect can implement, this simple framework focused on reducing and managing exposure to toxicants within the home environment will go a long way toward creating better health outcomes for the people who live in the spaces we design.

It is important to note that this is a process with inherent conflicts. Research is ongoing, shifting away from stand-alone materials toward concepts like systems thinking, life-cycle costs, and triple bottom lines. Exciting approaches such as biomimetics are expanding rapidly. Now is a thrilling time to be part of this work—there is so much yet to be done, but get started today by joining the AIA 2050 Materials Pledge at aia.org!